Meat, Plant-based Food, Solid Oils and Fats

- Home

- Meat, Plant-based Food, Solid Oils and Fats

Meat, Plant-based Food, Solid Oils and Fats

Alginate binds and molds food materials such as meat through a gelation reaction. Unlike enzyme reactions, such as transglutaminase (TG), it can bind various materials together, including meat, fish, and vegetables.

Applications and effects

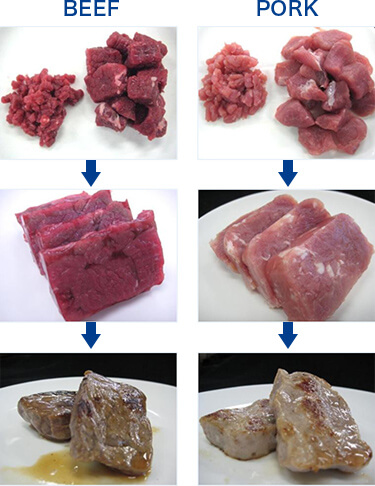

Binding and molding of meat

Any materials can be bound with no disintegration after heating.

Alginate forms a heat resistant gel when it reacts with calcium. By applying this reaction, it is possible to fill and firmly bind the gaps between pieces of meat with alginate gel.

While the most commonly used method for meat binding involves enzymatic reactions, like transglutaminase (TG), these enzyme reactions have substrate specificity, limiting the range of materials they can bind. Whereas alginate can bind various materials together by filling the spaces between the individual pieces, making it suitable for a wide range of materials. Regardless of the type of meat, fish, vegetables, or any other material, alginate exhibits the unique ability to bind them together.

The gelation of alginate does not require heating or cooling. Raw ingredients can be bound and molded as they are. Furthermore, the gel formed by alginate does not dissolve with heat, allowing the formed meat to maintain its adhesive state even during cooking, preventing it from falling apart.

Another advantage is that alginate does not contain milk-derived components like casein, eliminating concerns about allergies.

Recommended dosage

0.1~0.5% of total amount

Plant-based Food

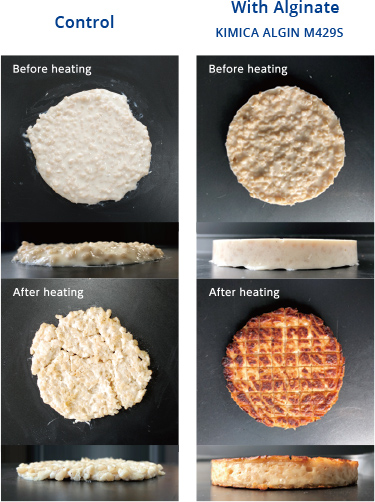

Create a plant-based burger using seaweed-derived alginate.

Recently, processed foods known as “plant-based foods” using plant-based proteins such as soybeans have been gaining attention. Initially considered as food for vegetarians, plant-based foods are also now recognized as a technology to reduce environmental impact and achieve a sustainable society.

Among plant-based foods, “plant-based meat,” which uses plant-based proteins such as soybeans instead of animal meat, has particularly attracted attention. Unlike animal meat, the plant-based proteins used in plant-based meat do not have the same stickiness even when mixed together.

Therefore, to create processed foods like burger patties that resemble ground meat, a strong “binder” with high adhesive properties is required. Additionally, it is preferred for this binder to be plant-based. Seaweed-derived material, alginate, is a valuable binder in such plant-based meat products.

Alginate can bind plant-based proteins and shape the burger patty using the same principle as described in “Binding and molding of meat”. Since gelation of alginate does not require heating and cooling, the process of molding is simple. Molded gelled products are not sticky and easy to handle and can be stored frozen in the raw state. As the alginate gel is heat resistant, cooking of the molded burger putty does not disrupt its shape. Food texture after cooking can be adjusted by changing the viscosity, M/G ratio or alginate dosage.

Recommended dosage

2~3% of total amount

Solid oils and fats (Substitute for pork fat)

Healthy solid vegetable oils and fats can replace pork fat.

Replacement of animal fat (pork fat) that are kneaded into weiner or bologna sausages with vegetable solid fats can reduce the intake of cholesterol and saturated fatty acids. Solid vegetable oils and fats, such as margarine and shortening, can be used but not as a substitute because they have distinctly different properties to pork fat. Therefore, alginate is used to process solid fats and oils that closely resemble pork fats.

Solid fats and oils using alginate are emulsion gels made by adding calcium to an emulsified solution of alginate and vegetable oil. When this is used as a substitute for pork fat, the following advantages can be obtained.

Intake of cholesterol and saturated fatty acids can be reduced to prevent lifestyle-related diseases.

No issues with trans fatty acids because alginate is not chemically modified (hydrogenated)

High water content (50%), so calories are reduced

The shape of the gel can be easily controlled and handled

Alginate gels are heat resistant so there are no issues with melting or collapse when heated

When heated, the emulsion gel breaks down, the oil and/or fat become liquid, which can reproduce dissolution of fat.

Alginate to be used

SEAKOL ALGIN M409

Recommended dosage

Solid oils and fats: 5~7% of total amount

Substitute for pork fat: 0.3~1% of total amount